Local Calibration

From a fingerprint to reliable figures: Eurofins Agro has extensive databases containing both NIR-spectra and data that have been generated by analysis using classical reference methods, for a large number of samples. By means of a mathematical model based on local calibration, Eurofins Agro is able to reliably derive a great number of different parameters. Of course, this method is continually being validated.

From NIR-spectrum to reliable analysis data

NIRS, or Near-InfraRed Spectroscopy, is a spectroscopic method that uses the nearinfrared region of the electromagnetic spectrum (from 800 - 2500 nm). Eurofins uses NIRS to analyse roughage, raw materials and soil samples. The main bottleneck for this method is the mathematical model used to calculate the desired parameters based on the NIR spectra. Eurofins has developed a model based on local calibration, that calculates a large number of parameters with very high reliability.

Secondary technique

A NIR spectrum contains a great deal of information about the organic matter in a sample. The trick is to know how to get this information from the spectrum. Because of the complex composition of feedstuffs such as maize or grass, direct deduction is not possible. For this reason, the technique is calibrated for each parameter separately. This means that for a large number of samples, not only is the NIR spectrum recorded, but the various parameters are also determined through conventional techniques. These classical methods offer the possibility of deriving the parameter values directly from calibration standards; hence, they are called “primary analysis techniques”. NIRS is calibrated based on the results of these primary techniques, and is therefore called a “secondary” method.

Reference samples

Over the years, Eurofins has set up a large number of calibration sets containing data from samples that are analysed by both NIR and reference methods. Eurofins has separate databases for all common roughages, raw materials and Total Mixed Ration (TMR) types. These datasets (NIR spectra plus reference values) contain from 1,000 to over 20,000 records, varying by type of material and parameter value. Because of smaller product variation, smaller calibration sets are required for raw materials; from at least 500 to over 1,000 records. All calibration sets include data from multiple harvest years.

Global or local calibration

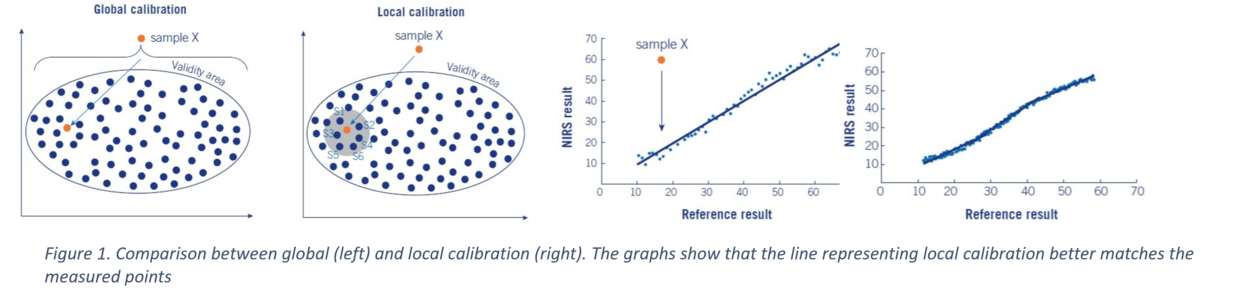

We have developed mathematical models to translate NIRS information into reliable data. In contrast to many commercially available global NIRS analytical models, Eurofins uses a model that works on the basis of local calibration. Global calibration, on one hand, involves a fixed calculation model. For this, all available information is used for each calculation to determine the parameter values of the unknown samples. Local calibration, on the other hand, has a computational model which focuses on the spectrum of the sample. Through an automatic search, this spectrum is combined with a number of spectra from the corresponding calibration set, that resemble the measured spectrum. For a good local calibration, hundreds of similar NIR spectra are needed. These reference spectra are then entered into the computational model, together with the corresponding primary analytical data to calculate the different parameters for the unknown sample. This approach has the advantage of the calculation being accurate even when the relationship between the NIR spectra and an analysis feature is not linear, as shown below.

Deviating samples

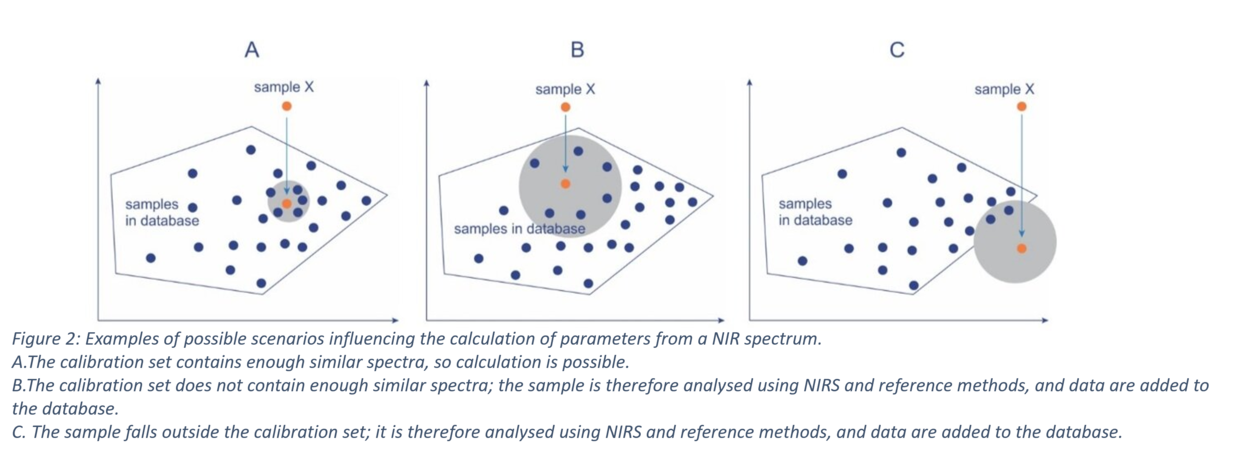

Sometimes a calibration set contains insufficient spectra that are similar to the spectrum of an unknown sample. If so, a calculation based on local calibration will not be sufficiently accurate. This may be the case for a single parameter or for many of them. In such a situation, the appropriate analysis will be performed using classical reference methods. This is always an option, since NIRS is a non-destructive analysis method. This will not affect the client’s analysis costs, but may lengthen the time of delivery. When the results of the reference analysis are within the parameter framework, the resulting data will subsequently be added to the calibration set. In this way, the database is continually extended and adapted to the current analyses. In fact, the NIRS calculation model of Eurofins is never completely finished. For example, changing weather conditions, progressive management insights, new harvesting methods and crop varieties will keep changing the composition of test samples, and thus the composition of the calibration sets (see Figure 2).

Standard crude ash measurement

Standard NIRS calculation models can miscalculate the parameter values when the roughage under analysis is contaminated with soil. Inorganic substances which exist in the soil will not produce a NIR signal. Therefore, these models calculate the content of the inorganic substances, or the crude ash content, indirectly from a NIR spectrum. This works well when it comes to vegetative inorganic substances such as silicates, which are encapsulated in plant cell walls. However, soil contamination is not visible through this method, while the risk of soil contaminating the roughage is real. For this reason, Eurofins always determines the crude ash content in roughage in the traditional way. Other parameters are determined using NIRS and based on the crude ash content measurement, are converted to dry matter values. In this way, Eurofins Agro is able to deliver reliable results, even in a situation of higher crude ash content.